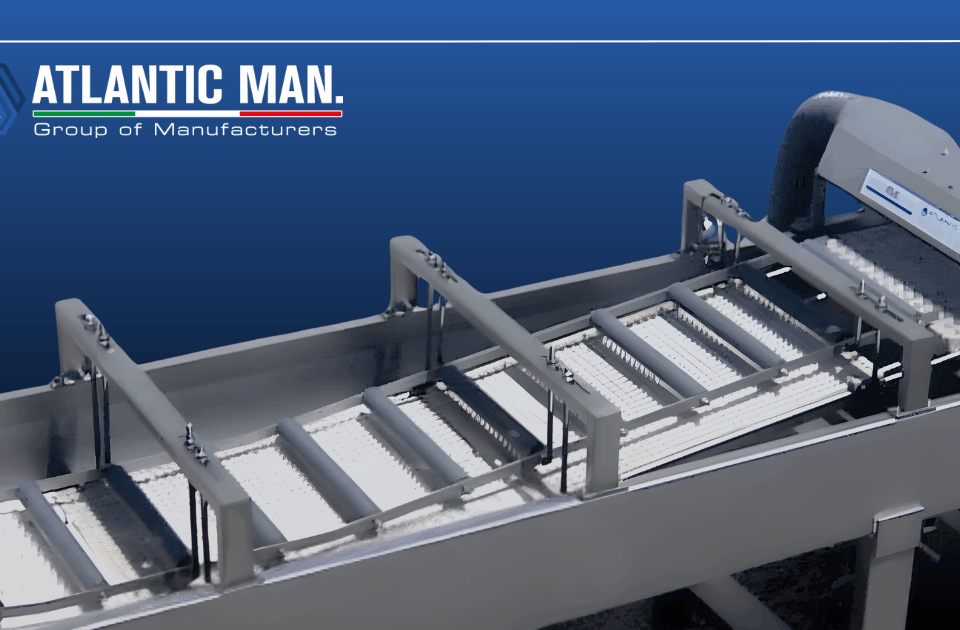

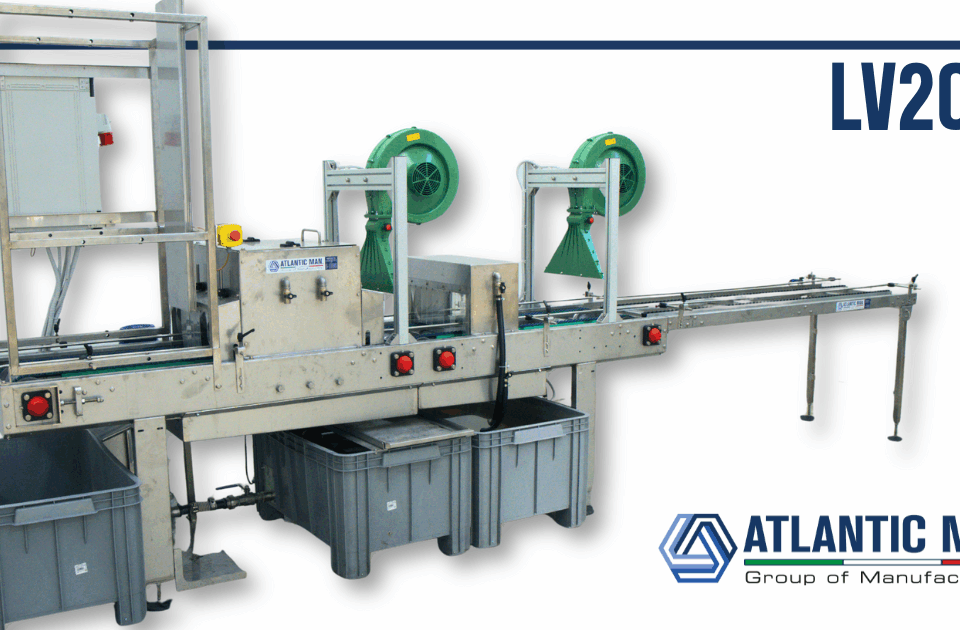

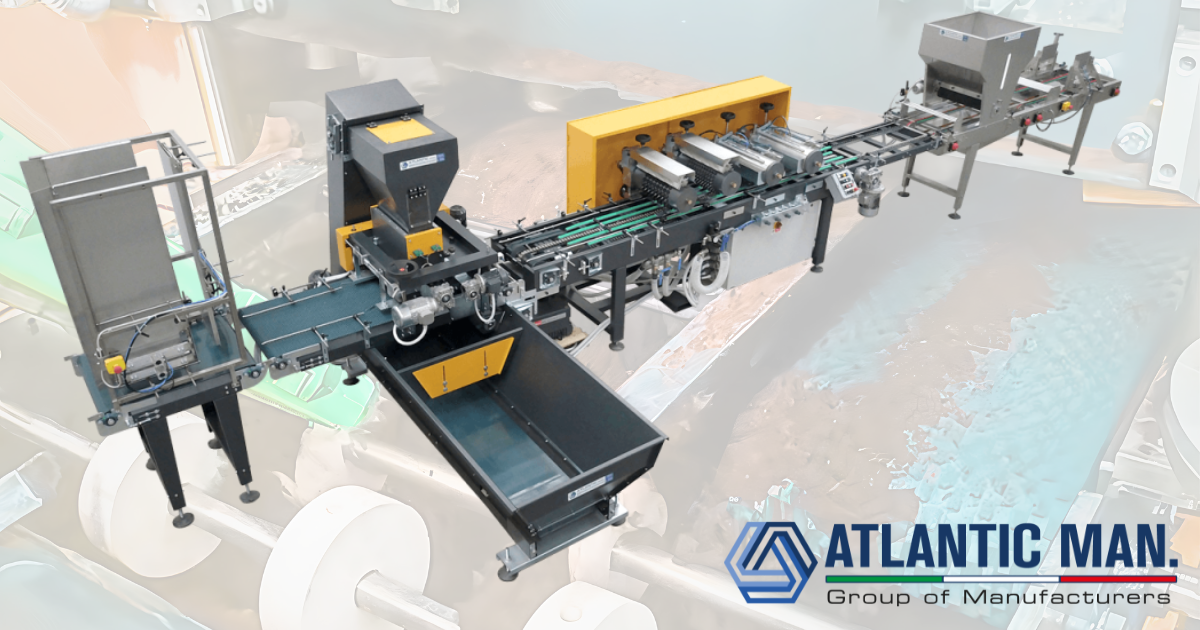

In the world of automated seeding, every detail matters. One of the most critical moments is the transition between the filling module and the seeding module — a delicate phase that can affect both process accuracy and production efficiency. To meet this need, our modern machines are now equipped with a solution that is both simple and effective : the motorized roller for container detachment .

The Challenge: Substrate Loss and System Failures

During the transfer phase, peat, soil, and other substrates may scatter and cause unwanted dirt and debris. If these materials reach the seeding module, they can interfere with the photocell systems, triggering processes at the wrong time and compromising the entire production cycle.

Solution: Motorized Roller Ensuring Accurate Transfer

The motorized roller is designed to ensure a more precise separation between the belt of the filling module and that of the seeding module. This creates the necessary gap for excess peat to fall onto the underlying recovery belt, which channels it back into the hopper, preventing waste and ensuring a cleaner, more organized working environment.

Why Choose a Motorized System?

Without a motorized system, widening the gap could cause thermoformed containers — being flexible — to fall, compromising the entire process. The motorized roller, on the other hand, allows for stability and precision, optimizing the efficiency of the whole system.

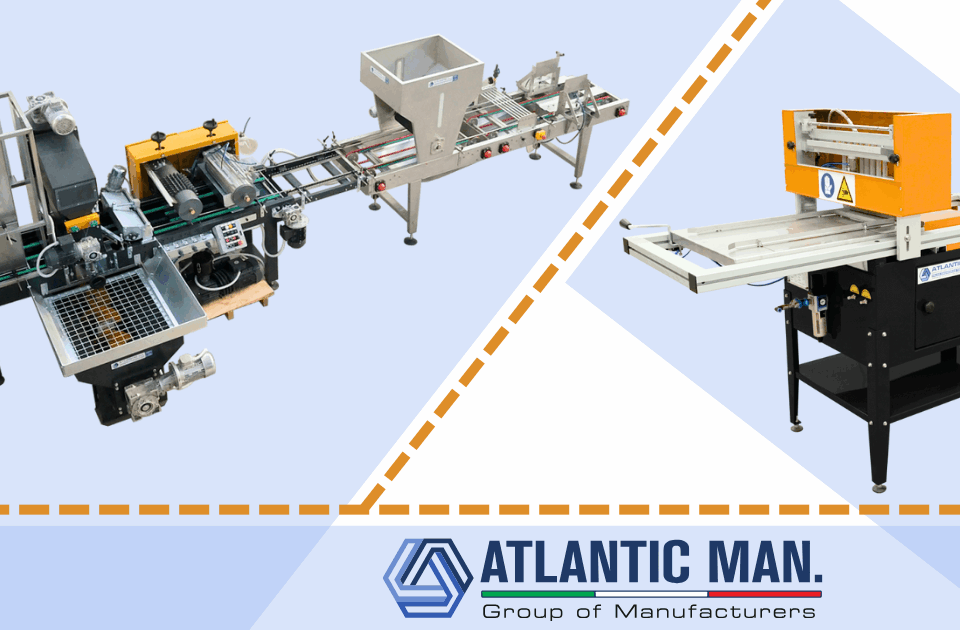

A Game-Changing Innovation

Until a few years ago, solutions like this did not exist. For Atlantic Man. they now represent a standard feature in their machines, while for other market players they remain just an optional extra. This solution allows us to offer our customers increasingly high-performing, reliable, and cutting-edge tools.

With the motorized module for container detachment, seeding becomes even more efficient and precise, reducing waste and optimizing the entire production cycle. A step forward for those who, like Atlantic Man. , always strive for excellence.