An alternative application of our drum seeding system.

In addition to greenhouses for horticultural production, in recent years there has been a significant increase in forest nurseries, whose main purpose is to protect the environment and biodiversity: plants cultivated in these structures, once grown, are transplanted to carry out reforestation measures, thus contributing to the creation or restoration of natural ecosystems and the safeguarding of our planet.

In Northern European countries, because of their geography, forest nursery activity is widely practiced. However, crops and management of production operations are very different from traditional ones and require specific systems and measures. At Atlantic Man., to meet these different needs, we have adapted one of our seeding solutions.

Background

An Estonian customer approached us to optimize the sowing process of his forest plants. The main challenges to address were the type of seed to be processed and the size of the tray: compared to horticultural seeds, in fact, forest seeds are much more irregular and less selected, and the plastic trays used for seeding, being much taller, require larger quantities of peat to ensure uniform filling of the cells.

These aspects necessitated the revision of some standard machine functionalities for managing the seeding cycle.

Solution

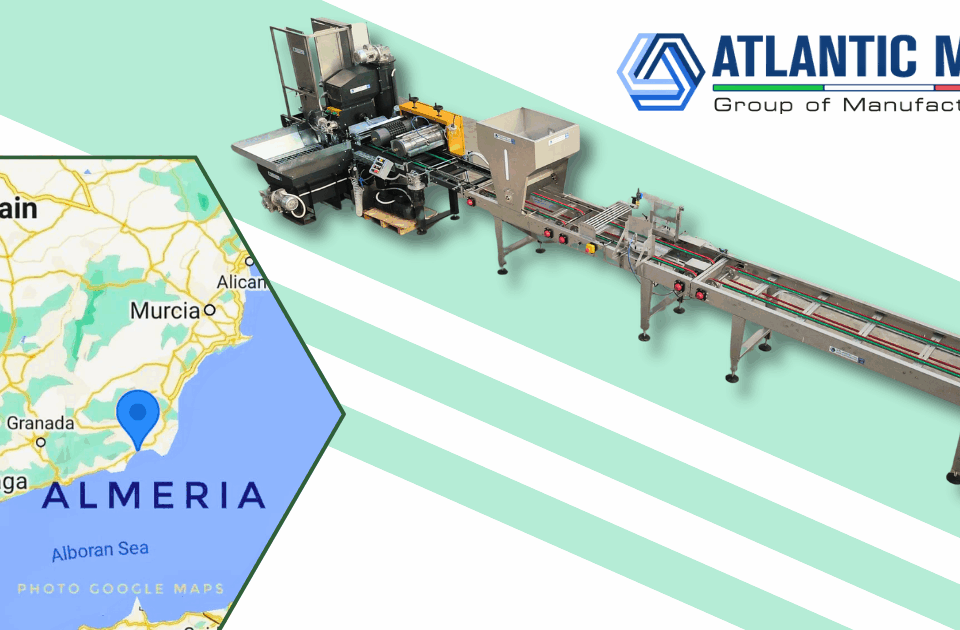

To meet the client's needs, we have configured our TTL800 drum seeding line according to the new type of tray to receive and the characteristics of the seed to be cultivated: the adjustable height of the various tools assembled on the line (peat presser roller, drilling plate and sowing drum) and the possibility to easily replace the insert bars based on the seed variety to be treated make this technology suitable for forestry production as well.

This seeding system can automatically handle up to 800 trays per hour and its compact design allows a single operator to supervise the entire process.

How it works?

Here's how the seeding process of spruce on 81-hole forest trays occurs:

Once manually loaded on the conveyor belt, empty trays are conveyed to a high-capacity loader that fills the cells with peat or soil. Subsequently, a drilling plate accurately creates the hole in which the seed will be released through the drum equipped with insert bars.

To maximize the efficiency of this seeding line an optional automatic destacker for empty trays and a completion unit for covering and watering the seeded cells can be integrated.

Atlantic Man. for forestry... and more!

By continually investing in research and development, we are now able to customize our systems to promptly meet various cultivation needs: consult our catalogue to find the most suitable technology for your greenhouse or nursery and contact us to learn more!