Atlantic Man. offers a wide range of systems for washing and disinfecting seed trays.

Inside greenhouses and nurseries, a good habit to practice at least once a season is to wash and disinfect seed trays before subsequent uses: in this way, not only the proliferation of pathogens that risk weakening protected crops and compromising their development is prevented, but unnecessary waste is avoided, saving space inside the structure and money for the purchase of other containers, being able to reuse the same for several seeding cycles.

Atlantic Man. provides to horticultural professionals the widest range of automatic solutions for the washing and disinfection of trays and crates for seedlings, suitable for any greenhouse or nursery configuration and able to thoroughly clean and sanitize supports of any material and size: we help you choose the most suitable system according to your production needs!

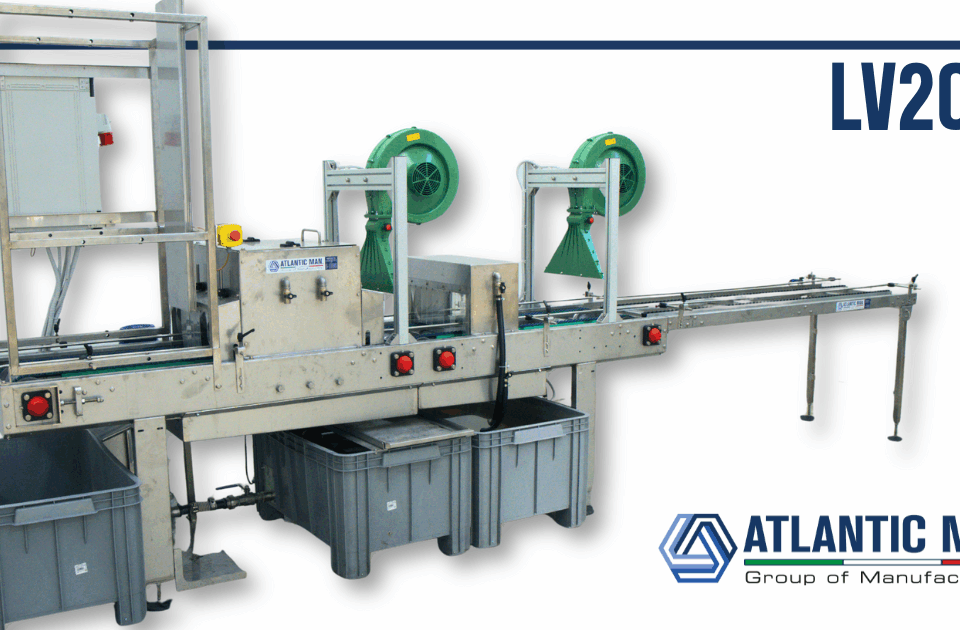

LV200 Tray Washing Machine

For those who need to meet low production requirements and want to introduce an economical washing and disinfection solution, our LV200 tray washer is the most suitable machine. This system allows to clean and sanitize up to 200 trays per hour in a non-intensive way and thanks to its compact design takes up little space and can be easily managed by a single operator.

Operation is simple: the operator manually loads the dirty trays one by one (or in the automatic destacker module, depending on the case and the type of tray), which are introduced inside the washing chamber for cleaning. At the end of the process, the trays are sanitized with a solution chosen according to the different crop needs and manually unloaded one by one (or automatically stacked).

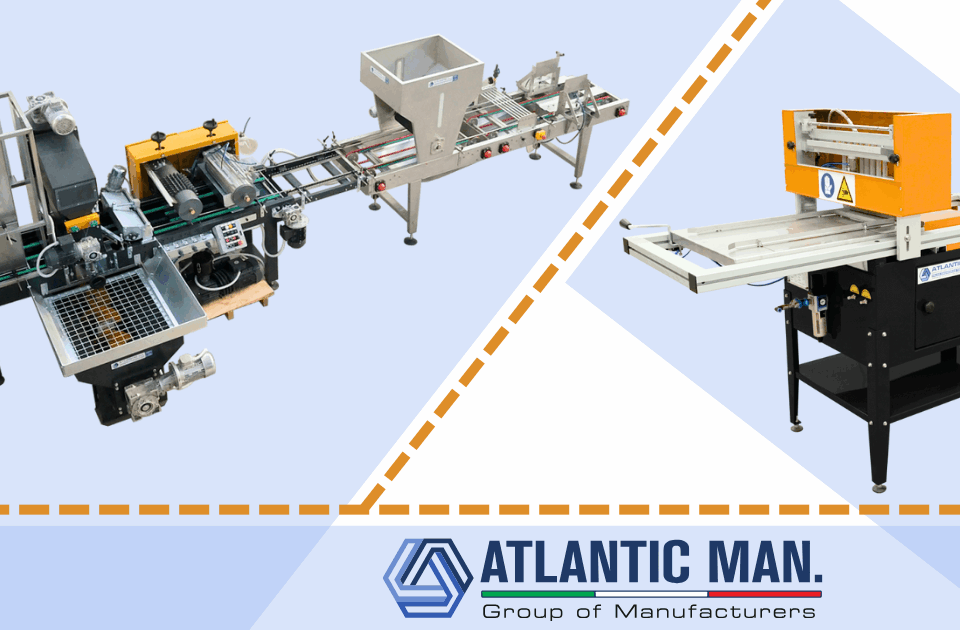

LV400 Vertical Tray Washing Machine

Our LV400 vertical tray washer can meet medium-high production needs, managing in an hour up to 400 trays and crates for seedlings in plastic, polystyrene and thermoformed of any size.

Once manually inserted inside the tray washer and positioned lengthwise, the dirty containers are subjected to the jet of high-pressure water nozzles that ensure effective cleaning, then to the brushing on both sides to remove the solid residues remained inside the cells or on the external surfaces and finally sanitizing with a disinfectant solution chosen according to production needs. To transform the work unit into a more efficient washing line, it is possible to optionally install a module for the automatic destacking of incoming dirty containers and a module for the automatic stacking of cleaned and sterilized trays.

LV1200 High-Capacity Tray Washing Machine

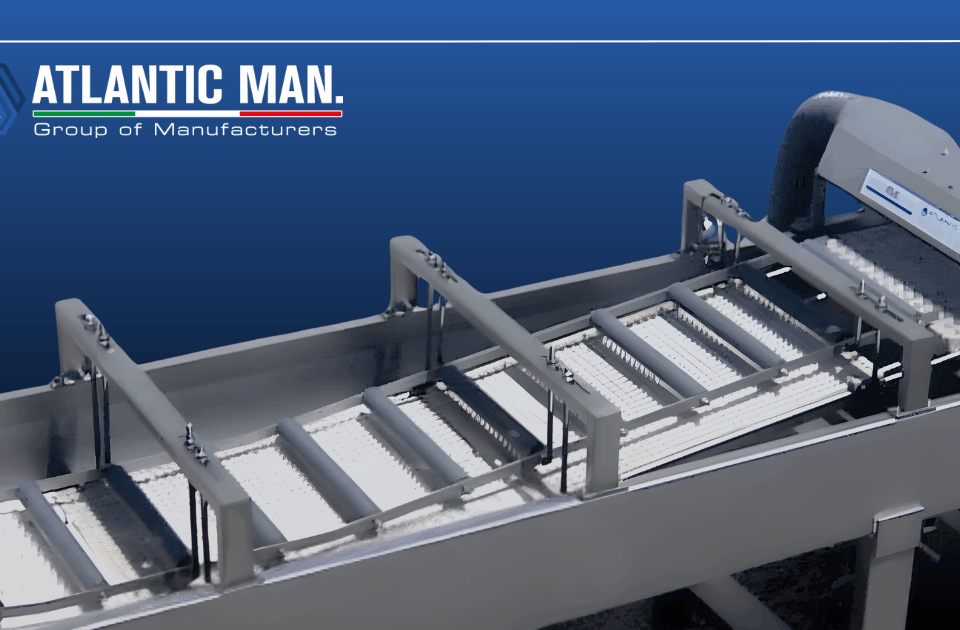

Our LV1200 high-capacity tray washer with overturning system achieves high cleaning and sanitizing performance: this washing line, in fact, can treat trays and crates for seedlings of any material and size, ensuring a production capacity of up to 1200 containers per hour.

The LV1200 tray washer is also available in the U-shaped configuration: with this conformation, the initial destacker of the dirty containers and the final stacker of cleaned and ready for sowing trays are positioned side by side and this allows a single operator to independently manage the entire washing and sanitization process.

The washing and disinfection procedure, however, is the same for both versions: dirty trays are piled upside down and automatically destacked, pass through the jet of 52 high pressure water nozzles for thorough cleaning, are mechanically brushed on both sides to remove any residues remained inside the cell or on the external surfaces and finally subjected to a sanitizing treatment. Once cleaned and disinfected, the trays are automatically stacked. For an even deeper cleaning and sanitizing process, an immersion tank for containers can be installed on the LV1200.

Want to know more?

If you are still undecided about the most suitable washing and disinfection system for your greenhouse, contact us for more information!