Atlantic Man. stands by Guamasa to optimize the seeding process of its protected crops.

Our company is always ready to meet new challenges, studying and developing technologies for greenhouses and nurseries that can perfectly meet the customer’s needs: in 2019 Guamasa, a horticultural business based in Tenerife, has relied on us for the improvement of the sowing process of its crops.

Background

Guamasa is a family-run nursery located in Tenerife, the largest island of the Canaries. Like many companies operating in the horticultural sector, because of its geographical position, even Guamasa has had to deal with the increasing difficulty in recruiting skilled workers and the consequent slowdown of production operations, especially the stages of sowing. Moreover, the availability of small spaces does not allow the use of particularly large systems which risk hindering the smooth running of other activities in the nursery. The customer, therefore, has expressed the need to install inside its structure an automatic, space-saving seeding solution, easily controllable by a single operator.

Solution

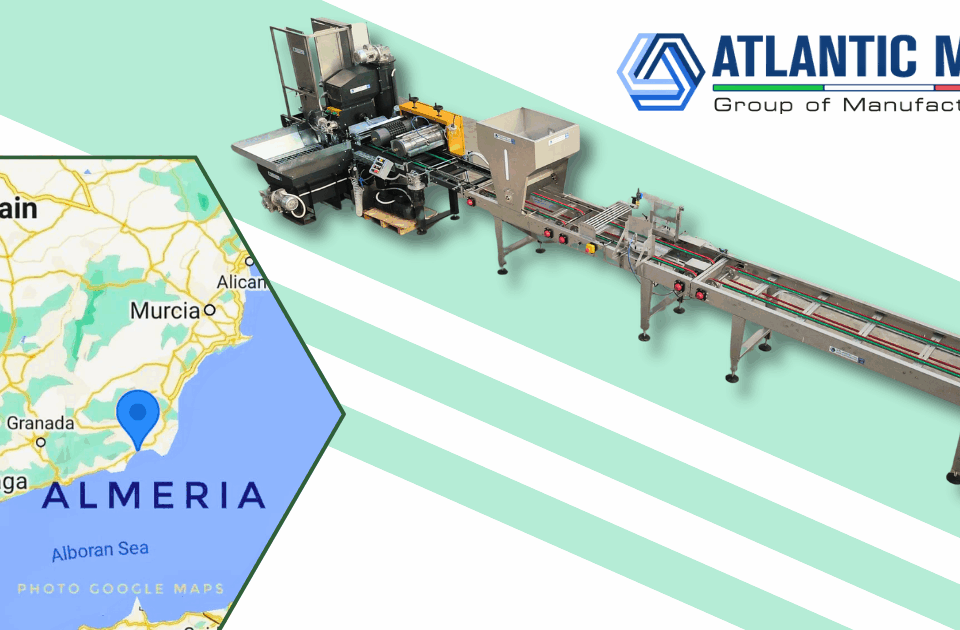

Together with our R&D team we have developed a product that best summarizes the demands of Guamasa, that is the need for greater autonomy to support intermediate production capacities occupying small space inside the nursery: this is how our TTL800 drum seeding line was born.

This versatile system allows to automatically sow the most varied types of seeds inside any type of support for seedlings, in particular polystyrene trays and plastic crates, thanks to a seeding capacity that reaches up to 800 containers per hour. The compact design of this seeding line saves space, and the entire process can be managed in complete autonomy and without difficulty by a single operator: the same tasks performed with a standard-sized machine, instead, would have required the employment of more than one insider.

How it works?

The operator loads the empty trays on a conveyor belt, which conveys them to the destacker; from here, the trays are automatically transported inside the machine and filled with peat before being subjected to the drilling mechanism that creates the hole in which the seed is released thanks to a sowing drum. The cells are then covered with vermiculite by a covering dispenser and watered by a series of perforated bars equipped with a solenoid valve. The seeding cycle ends with the automatic stacking of ready containers and their transport on a dedicated conveyor belt for the final accumulation.

Guamasa has also chosen to optionally install a vertical big bale loader that automatically feeds the TTL800 with a homogeneous compound suitable for sowing trays, thus transforming the single unit into a complete working line and achieving exceptional levels of efficiency and automation.

Customer's satisfaction

Choose the right system for your greenhouse!

You’re looking for a tailored technological solution for your greenhouse or nursery? Contact us: our staff will help you find the most suitable system for your protected crops, customizing it according to your needs!