Climate changes, higher energy prices and labour shortages invite to rethink the management of protected crops.

Despite being controlled environments, greenhouses and nurseries are not immune to the great challenges of the time we are currently experiencing: the climate change, the increase in electricity prices, the water crisis and the limited availability of skilled labour are just some of the situations that are challenging those who manage protected crops. By optimizing the organization and using the best technological solutions, however, it is possible to effectively address these environmental and logistical difficulties: let’s see how.

Climate Changes

Climate changes can be seen from two ambivalent perspectives: while global warming and air pollution have registered an increase in greenhouse horticultural production, being able to count on an overall healthier climate for the growth of the seedlings, on the other hand, the frequent temperature changes and the high rates of humidity can encourage the proliferation of parasites or other pathogens able to compromise their development. It is possible, however, to contain the problem by washing and sanitizing with care seed trays before the subsequent uses and periodically treating the crops with solutions for fertigation.

Our LV1200 tray washing machine, available in both standard and "U" version, allows to automatically clean and disinfect trays, crates, and boxes for seedlings of any material and size, representing a true ally in the fight against the development of species harmful to crops.

Energy Crisis

Climate change has been one of the many factors that have led to rising power costs and water scarcity: the horticultural field has also been tested in recent years by these price increases. By investing in modern and more efficient systems, however, it is possible to cultivate sustainably by reducing the consumption of energy resources such as water and electricity, avoiding waste and saving on the overall operating costs of the structure.

Our irrigation booms can be programmed to deliver to the protected crops only the amount of water and nutrients they need, allowing significant water savings compared to manual irrigation and most of the irrigation systems available on the market.

Low Labour Availability

Those who own a greenhouse or a nursery also have to deal with the limited availability of skilled workers that risks slowing down all productive activities. Moreover, the advent of increasingly advanced computer systems leads to estimate that in the next few years manual operations carried out within these structures will be in constant decrease, until it will be necessary the automation of the entire production process, starting from sowing trays.

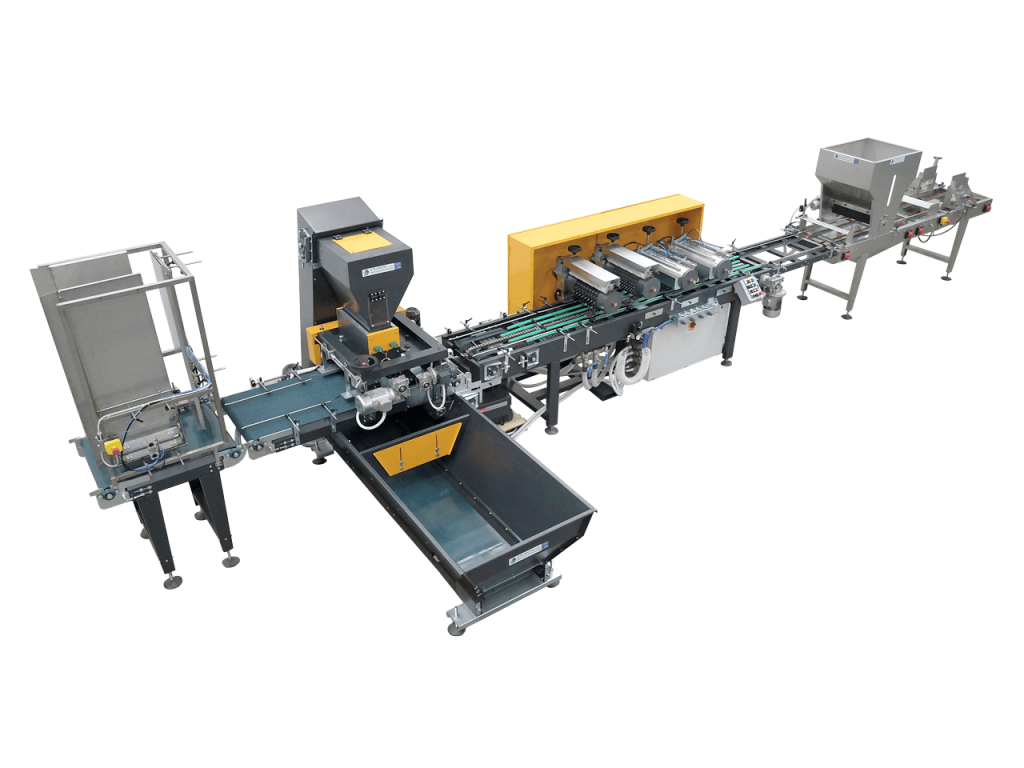

Our TTL1200 drum seeding line allows to automatically manage the stages of filling, drilling and sowing, covering and watering trays for seedlings of any material and size, thanks to a production capacity that can reach 1200 containers per hour.

Atlantic Man. can help you!

You have a greenhouse or a nursery and you're facing even one of these problems? Our systems can help you: contact us to find the most suitable technologies to protect your crops!