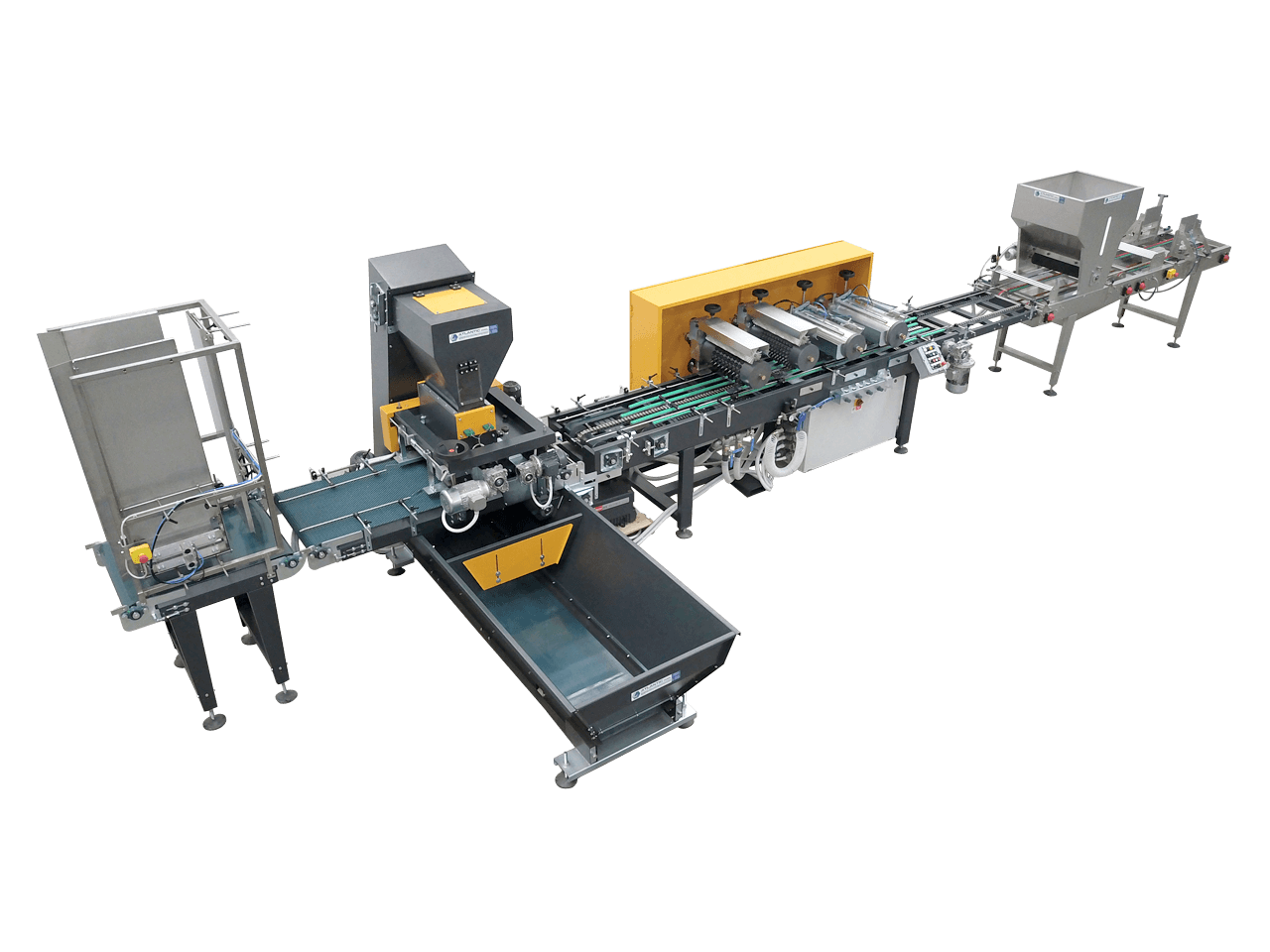

The drum seeding line TTL1200 made by Atlantic Man. is a fully automatic system suitable for sowing plastic, polystyrene and thermoformed trays for seedlings of all sizes. This seeding line guarantees high performance, thanks to a seeding capacity that can reach 1200 trays per hour. The TTL1200 seeding system consists of separate modules dedicated respectively to filling, drilling and sowing, covering and watering: once automatically destacked, empty trays are transported inside the machine and filled (thanks to our Peat Filler RT25), before being subjected to drilling and seeding drums whose height can be easily adjusted. Next, a drum operated by limit switch distributes the vermiculite in the cells and five perforated bars equipped with a solenoid valve proceed to the watering of the trays. Finally, the seeding process ends with the automatic stacking of the outgoing trays. The sowing takes place thanks to a sowing drum with brass insert bars equipped with micro-holes through which the seed is suctioned: the advantage of the patented insert bar system is that it is not necessary to replace the entire drum when converting production, but it is enough to replace the already installed brass bars with others with different drilling holes, depending on the size and shape of the seed you want to process, thus saving on the costs of the equipment supplied with the machine. It is possible to integrate further modules (“Advance” 2+2 or 1+3) for drilling and seeding to this drum seeding line, replace the drums to distribute the peat and vermiculite with a covering dispenser and add a loading bay at the beginning of the line and a final accumulation conveyor belt for stacked trays at the end.

Main features

- Automatic seeder for high production capacities

- Tray transported lengthwise; working speed up to 1200 trays per hour

- Suitable for all different types of plastic and polystyrene trays

- Separate modules for filling, drilling and sowing, covering and watering.

Watch TTL1200 in action

Operating stages/installed devices

- Automatic destacker of empty trays

- Tray filling with peat loading conveyor belt (Filler RT25)

- Tray transport system on filler conveyor belt

- Cleaning system with screw + brush to remove excess peat

- Drilling and seeding drums with height and distance adjustment to tray type

- Pneumatic control and adjustment console

- Vacuum pump for seed pick-up

- Vermiculite drum dispenser, operated by limit switch

- Shower heads for watering by 5 perforated bars with solenoid valve

- Automatic height adjustable stacker

- Electric control panel