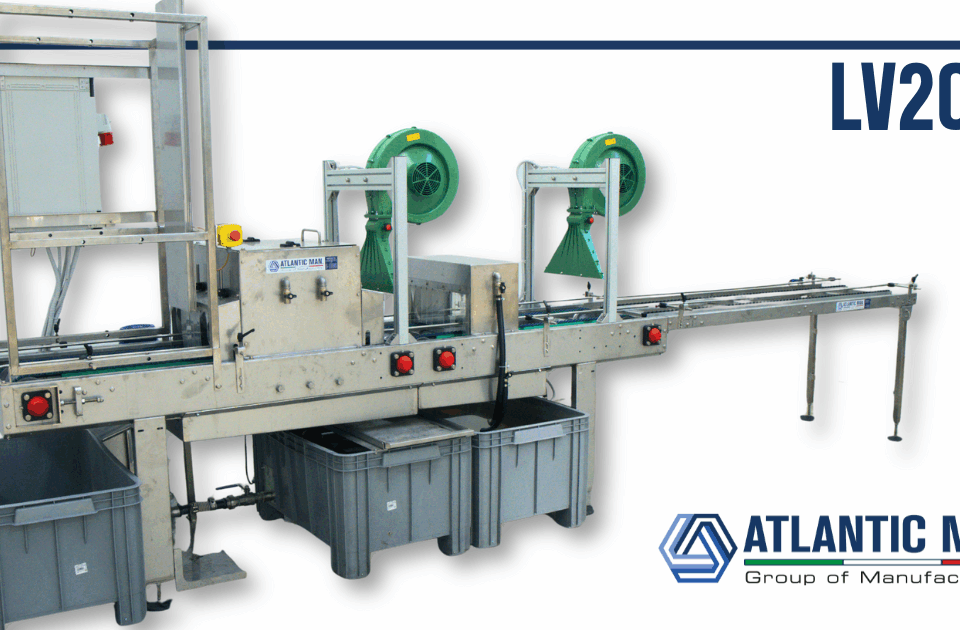

Our destackers are designed to handle trays and crates of various sizes and formats.

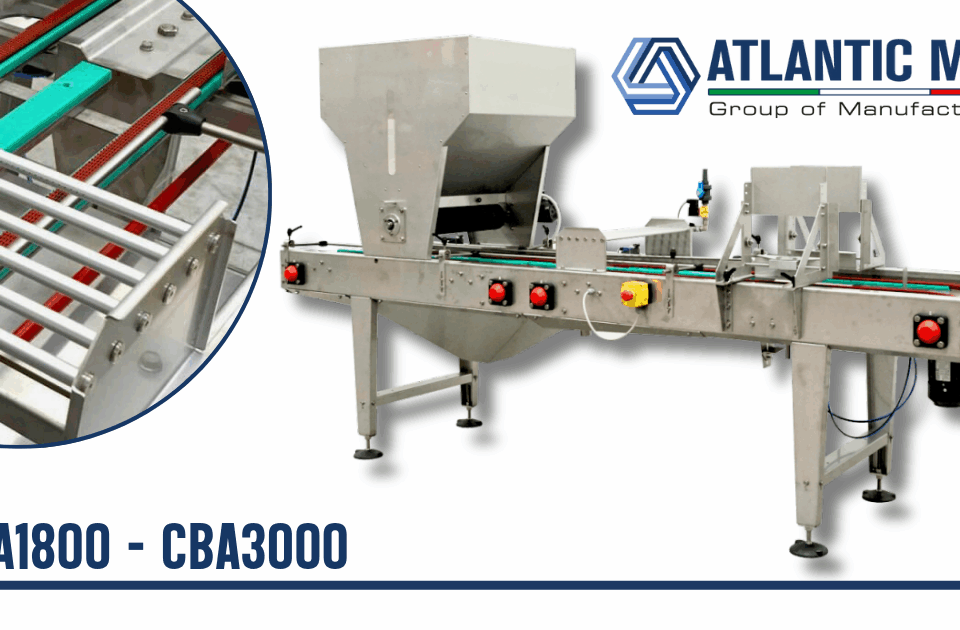

In horticultural greenhouses and nurseries, optimizing processes is essential for improving efficiency and reducing operational costs. Among these, the automatic destacking of seed trays plays a crucial role, allowing the quick and precise separation of stacked trays, ready to be used in automated production lines. Manually, this operation would require a dedicated operator to destack the trays and load them onto the conveyor belt. Automation eliminates this need, boosting productivity and reducing machine downtime.

Each type of tray requires a specific destacking solution to ensure a continuous, uninterrupted workflow.

Destackers for Different Tray Formats

The wide variety of seed trays available on the market today requires flexible destacking technologies tailored to each format. Our systems are designed to quickly separate trays of various sizes and materials , without compromising their integrity during the process.

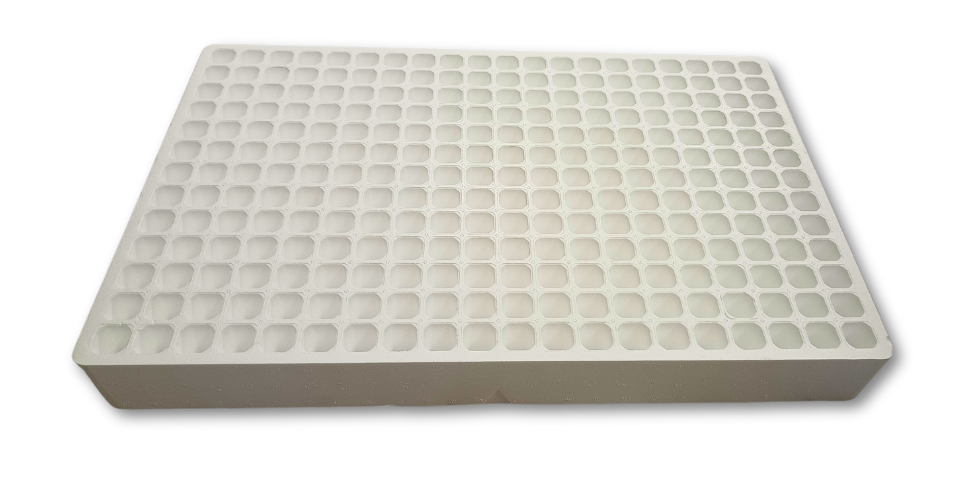

Rigid Polystyrene Trays

Polystyrene trays, known for their lightweight and durability, are ideal for multiple uses. However, their design requires a destacking system that ensures safe separation without compromising their integrity or insulating properties. Our solutions ensure fast and precise destacking, minimizing the risk of damage during handling.

Lightweight Thermoformed Trays

Thermoformed trays are appreciated for their lightweight and affordability, but they tend to stick together easily during destacking. To solve this problem, we have developed innovative technologies to gently separate the trays, preventing deformation and ensuring a continuous production cycle.

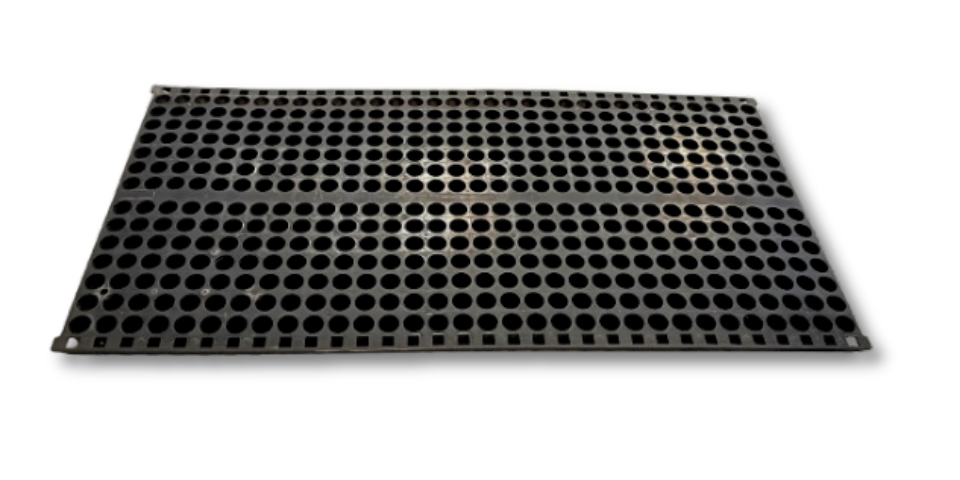

Japanese Trays

Japanese trays, made from flexible plastic, require a specific approach for automated destacking. Although they are thicker than lightweight thermoformed trays, their extreme flexibility and the high friction generated between the cells can make destacking complex. To overcome these challenges, we have designed destacking systems that ensure accurate separation, reducing the risk of damage during the process.

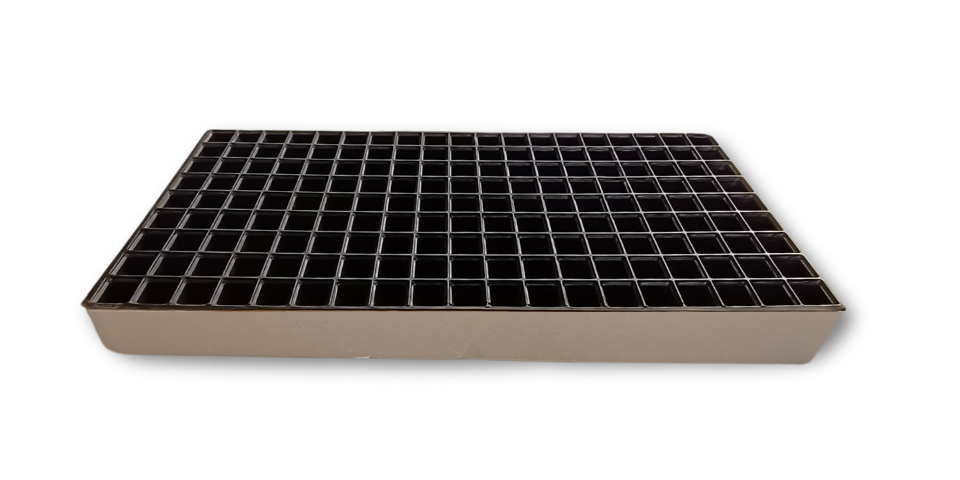

Trays with Plastic Insert

Polystyrene trays with plastic insert combine strength and functionality, making them suitable for various horticultural applications. However, their specific structure requires careful and reliable separation. For this reason, we have developed specialized destacking technologies to handle these trays efficiently.

Rigid Plastic Trays

Rigid plastic trays require special handling due to their heavier weight. In this case, it is essential to optimize the opening and closing times of the destacker blades and stops to prevent the stacked trays from slipping. Our technology ensures smooth and safe destacking operations even with particularly heavy trays.

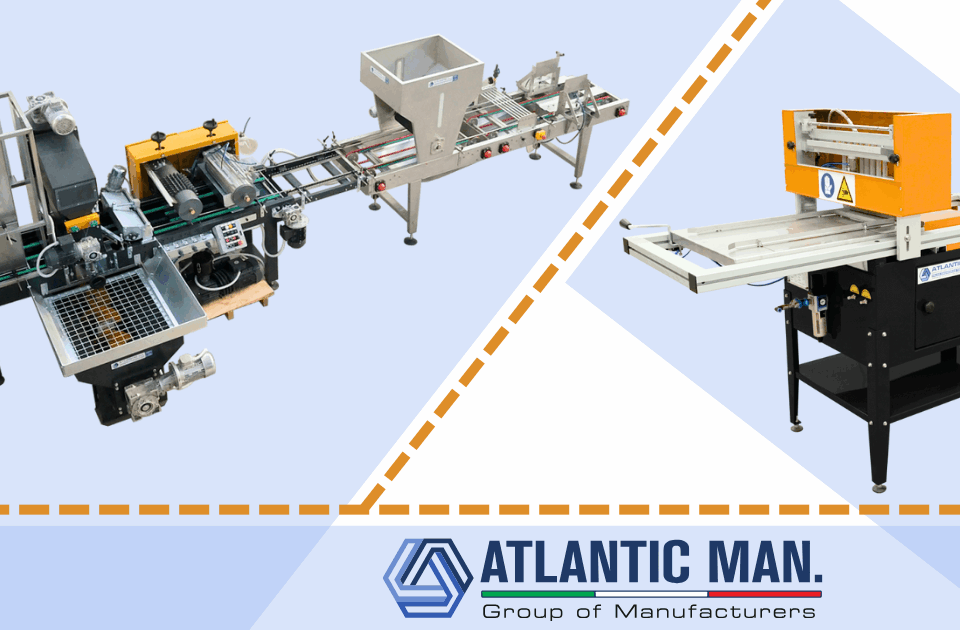

The Importance of Choosing the Right Destacker

Investing in an automatic destacking system is crucial to improving operational efficiency, optimizing production times, and reducing costs. Our unstackers are designed to integrate seamlessly with automated seeding lines, substrate fillers and tray washing stations, ensuring a smooth and uninterrupted production cycle.

Contact us to discover how our automation solutions can transform your greenhouse or nursery!