With minimal investment, even small greenhouses can optimize the horticultural production.

For those who run a small nursery business and want to automate production, the efficient organization of spaces is one of the main concerns: in particular, those with reduced space fear that the transition from manual operations to the introduction of systems and machinery may interfere with the performance of the usual management activities. However, today there are technology systems with a compact design that can adapt to different greenhouse or nursery configurations, so even the smallest facilities can make the most of their space available, automating processes and ensuring high quality standards on horticultural production.

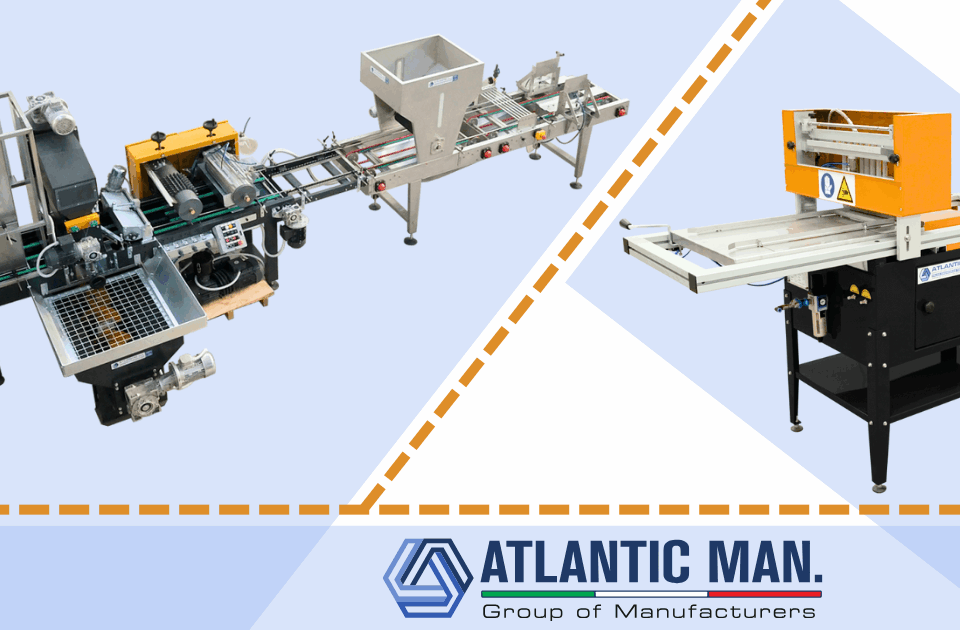

To manage the sowing process of seed trays inside greenhouses and nurseries with space problems, you just need two automated systems.

Step-by-step Seeder

Our PROMASTER is the most practical and economical seeding solution for those who have little space available and do not have particularly high production needs: this system allows to release with precision any type of seed inside different types of trays for seedlings and thanks to its pneumatic operation ensures an important energy saving compared to seeding lines that require electricity.

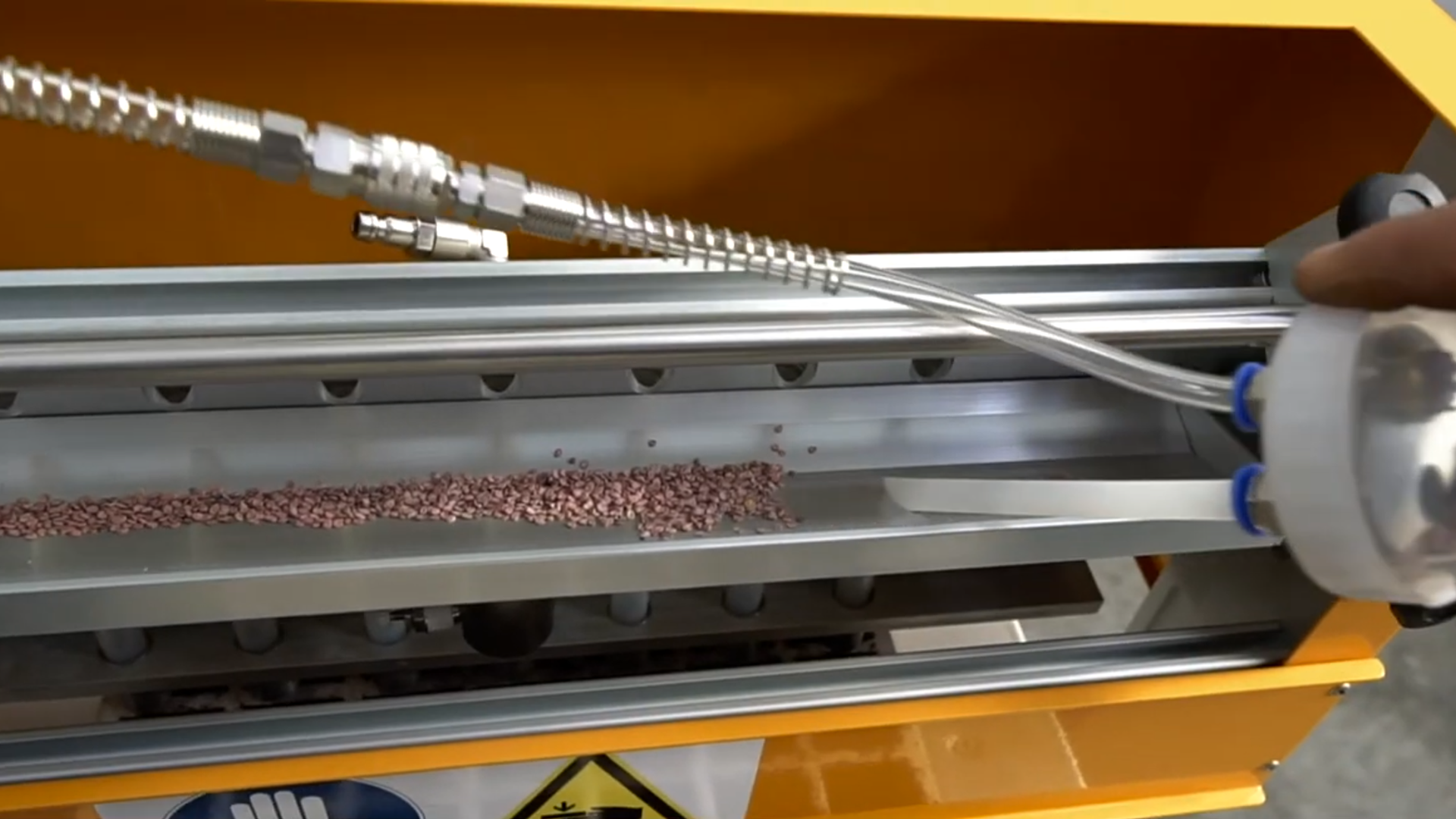

Drilling

After being manually inserted by the operator, the tray automatically advances row by row to be subjected to the drilling mechanism.

Seeding

Seeding takes place through a bar with brass nozzles that suctions the seed and place it inside the hole.

Seeds Recovery

Once the process is complete, the remained seeds can be recovered with a dedicated suction system.

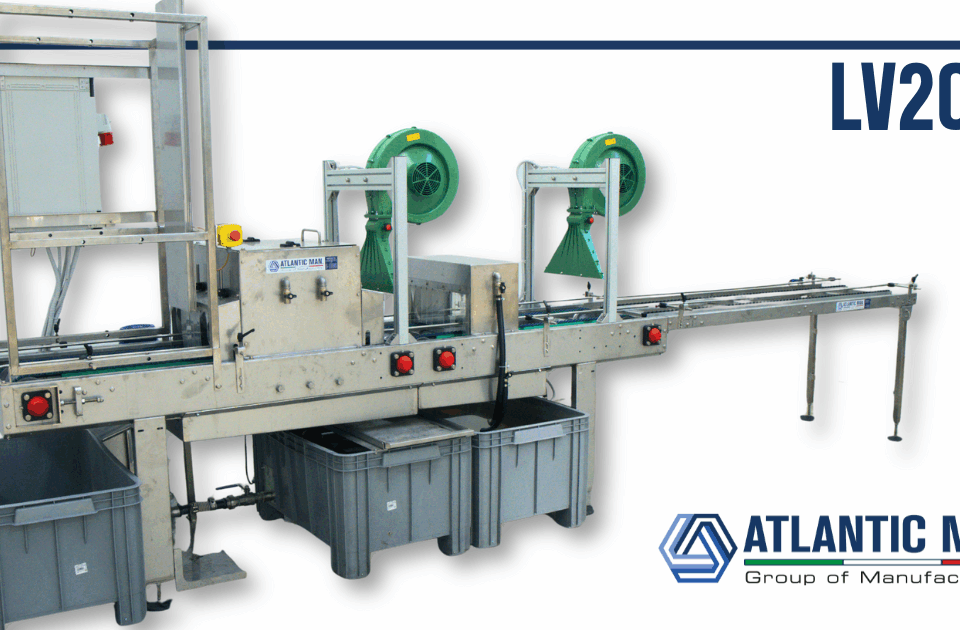

Module for completing seeding

To complete the seeding cycle, it is possible to combine the step-by-step seeder with the compact version (L=1800mm) of our CBA module, which combines three functions in a single machine: covering, watering and stacking.

Covering

The covering unit consists of a drum that covers the trays previously sown by spreading vermiculite.

Watering

Watering, however, takes place thanks to a system of perforated bar showers that bring water to the previously covered cells.

Stacking

Finally, the stacking unit automatically stack the outgoing trays, sorting them towards the germination process.

For a better management of spaces

If you have a small horticultural business and your workspaces are limited, do not give up the technology: contact us and we will help you find the most suitable systems for your greenhouse or nursery configuration!