An innovative feature for nurseries handling both traditional and organic crops.

In the protected agriculture sector, more and more greenhouses and nurseries are combining conventional cultivation methods and organic practices to offer a diverse range of products. These activities require differentiated crop management to ensure that organic crops are not contaminated by residues of chemical products used for traditional ones.

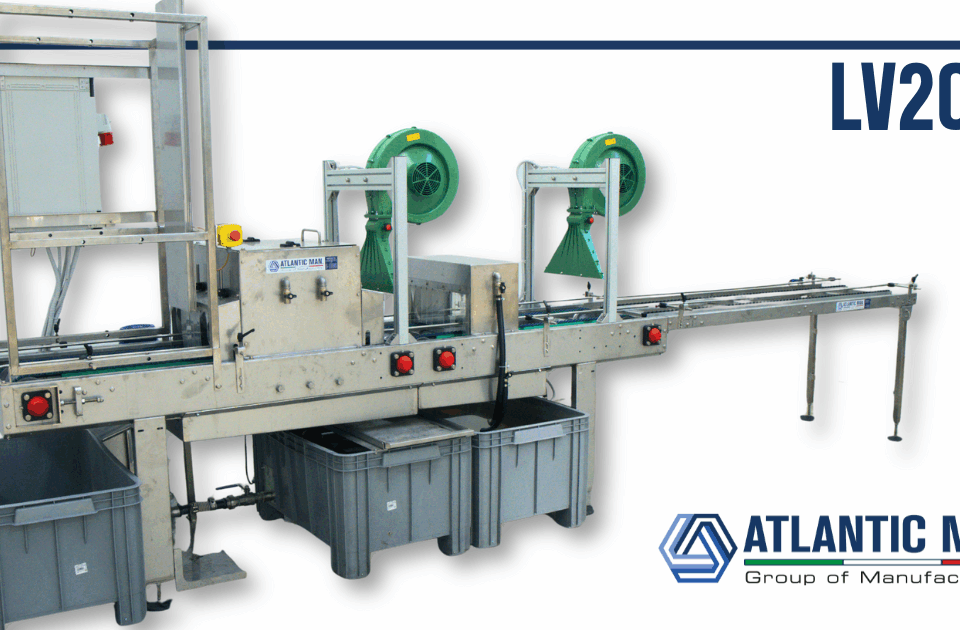

Our automatic hopper emptying system allows for optimized management and treatment of substrates for different varieties.

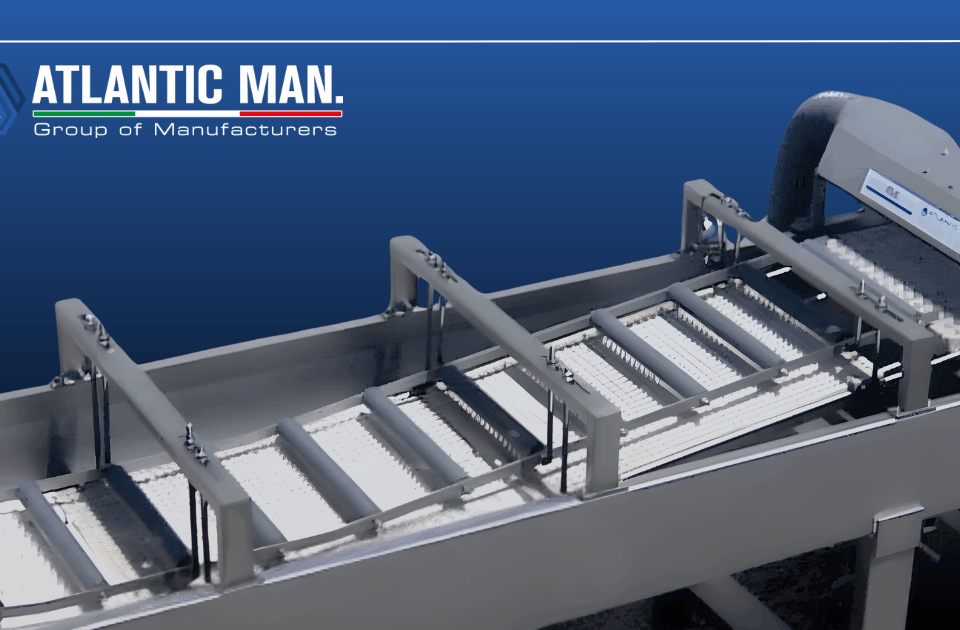

Hopper Emptying System

In our tray fillers, an optional feature can be integrated that drastically simplifies the change of peat between different types of crops. This system includes a button that, once activated, reverses the direction of the filler conveyor belt, allowing the hoppers to be completely emptied without manual intervention or the need for disassembly.

Operational and Ecological Advantages

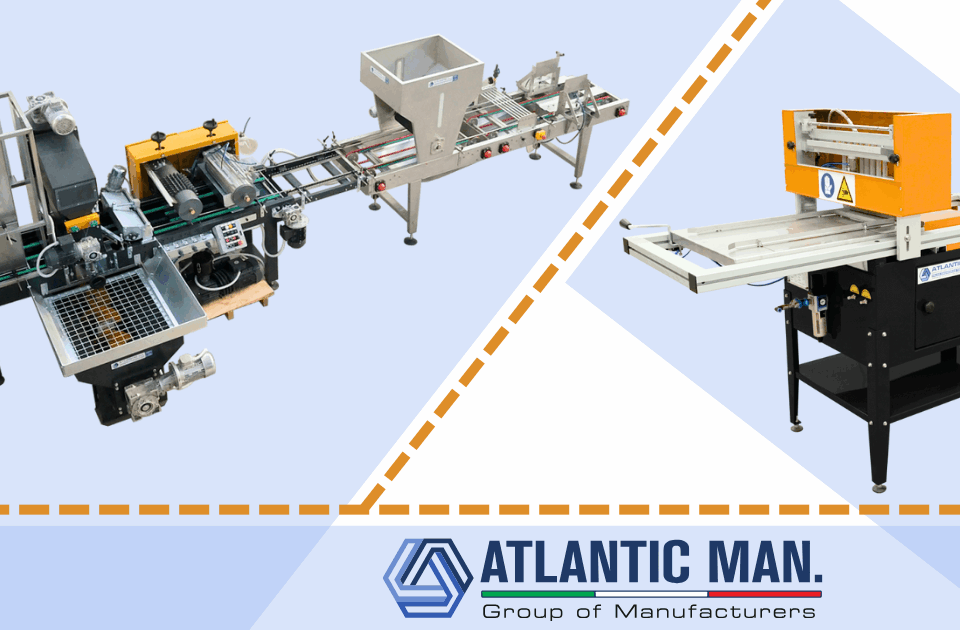

This system offers significant advantages from both operational and ecological perspectives. Firstly, it simplifies and accelerates the transition between the seeding of traditional and organic crops, effectively reducing the risk of cross-contamination in the substrate and maintaining the integrity of the production.

Furthermore, the introduction of automatic hopper emptying represents a significant step towards more sustainable practices. Thanks to this system, it is possible to recover excess peat or soil, minimizing waste and optimizing resource use.

Discover How to Optimize Substrate Management

Our peat and soil processing systems can revolutionize operations in your greenhouse or nursery. Contact us to learn more!