How to choose the big bale soil loader that adapts to your production needs.

The production operation cycle inside greenhouses and nurseries begins with the preparation of the substrate in which the seed will be sown: in order to ensure a proper growth of horticultural plants, in fact, it is essential to process with care the peat or the soil so that they achieve the optimal texture and humidity level before filling the trays. At Atlantic Man., we have perfected two automated loading systems that allow you to chop large volumes of pressed substrate (big bale), pouring in the hopper a homogeneous and ready-to-use compound.

Big Bale Horizontal Loader

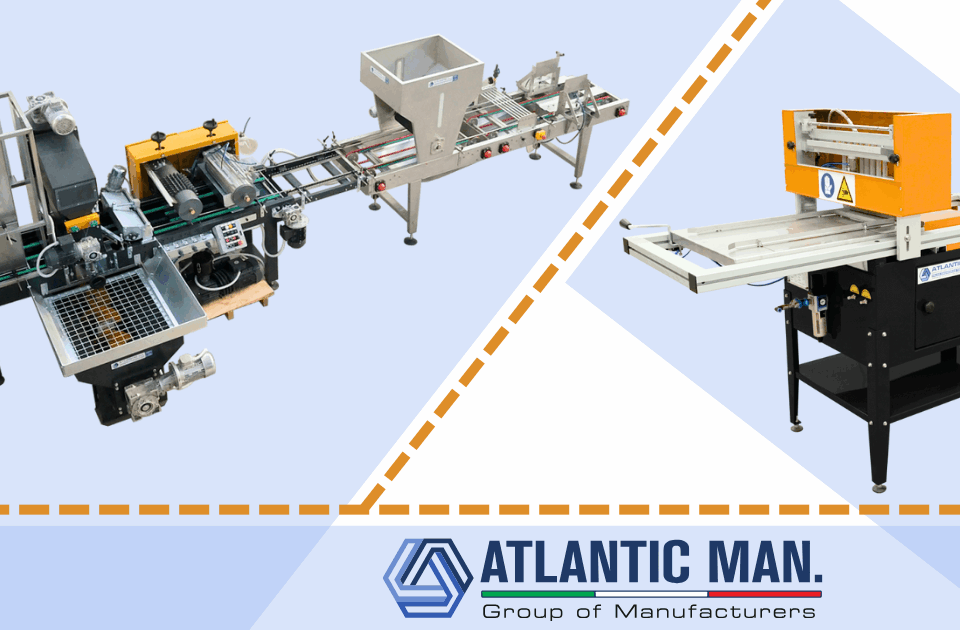

Our horizontal big bale loader is a truly versatile system: the possibility to move it easily into the work area, depending on the space requirements, makes it suitable for any greenhouse or nursery configuration. Moreover, it can be used as a single working unit, or it can be incorporated in a production line to feed other machinery, such as potting machines and seeding lines.

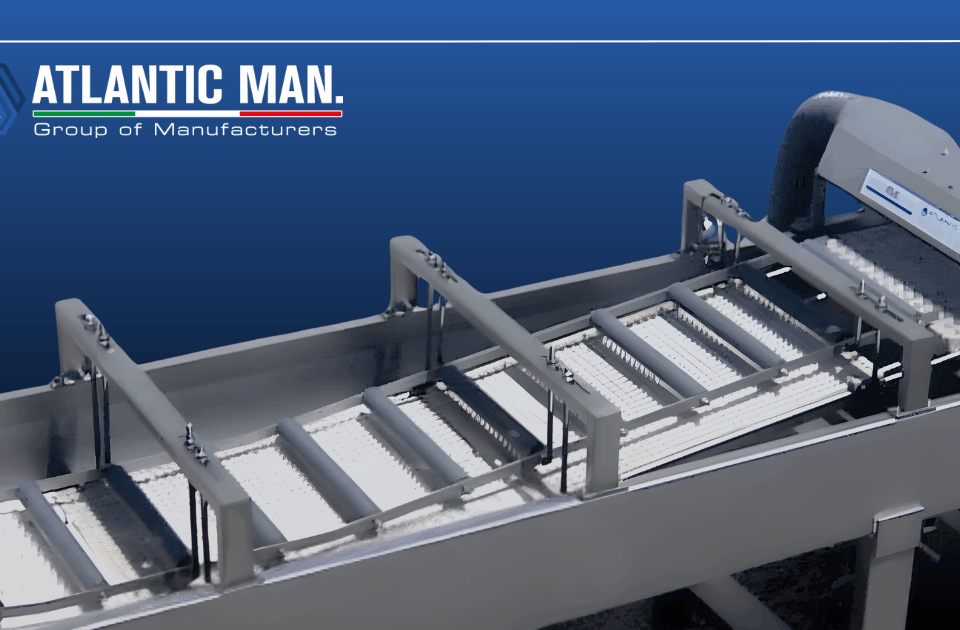

This loader, by shaving the bale on the side and working evenly throughout its height, allows the peat to be picked up simultaneously from the lower, moister part and from the upper, drier part, thus obtaining a homogeneous product during the entire processing phase. Thanks to the tilting processing system, the residual peat that remains inside the machine is minimal and this allows to speed up the bale replacement times, making this system particularly suitable for all productions that require large quantities of substrate in a short time.

Big Bale Vertical Loader

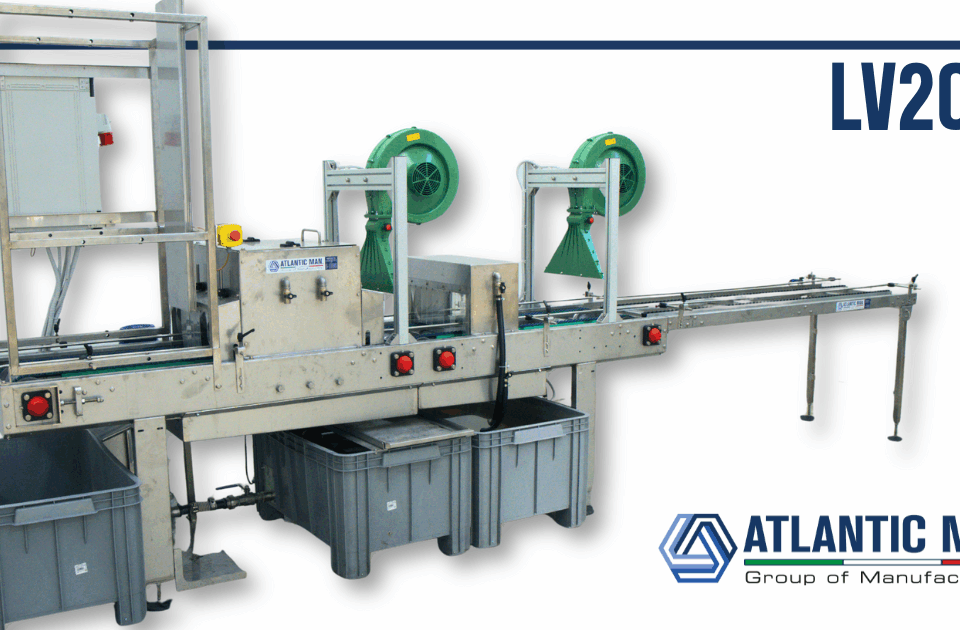

Our Big Bale V, thanks to its vertical extension, represents the perfect loading solution inside greenhouses with limited workspace and it can be used individually or in a working line together with other systems.

The shredding process of the peat bale is carried out through a toothed chain crusher, placed on the top of the machine, which proceeds horizontally: in this way the peat bale remains almost intact, and it is therefore possible to easily remove the remaining pallet to replace it with a different type. This system, being more closed off to the outside, protects the bale so that the fertilizers or chemical elements inside it do not evaporate if the peat should remain in the machine for some time without being used: the residual compound, therefore, can be stored in optimal conditions directly inside the loader, keeping it suitable for subsequent processing.

Which one to choose?

Our peat and soil loaders make a uniform compound and are equipped with all necessary protective devices to ensure operator safety: contact us to find the best system for your productive activity!